They say there is no substitute for experience, and when it comes to spaceflight there are few in the world that can match the proven expertise and decades of experience that Boeing brings to the table. Three companies are currently developing spacecraft to fill the void left by the retirement of NASA’s Space Shuttle fleet in 2011, and the Crew Space Transportation-100 spacecraft (or CST-100 for short) is Boeing’s answer to fill that void, leveraging their five decades of human spaceflight experience to provide the United States with affordable, reliable, and regular access to the ISS.

Boeing has remained rather low-key in the development of their spacecraft, or “space taxi” as they refer to it, which makes sense because that is exactly what it is. However, low-key is not to be confused with no progress. Boeing has been hard at work developing the vehicle they hope NASA will choose as a transport for their ISS crews.

“The CST-100 is a cheap, cost effective vehicle that doesn’t need to be luxurious because it only needs to hold people for 48 hours. It’s a simple ride up to and back from space,” said former astronaut and commander of the last space shuttle mission Chris Ferguson, who now serves as Director of Crew and Mission Operations for Boeing. “Our focus right now is making sure we build the vehicle the right way.”

The CST-100, which Boeing is developing in partnership with NASA’s Commercial Crew Program will be capable of ferrying a crew of up to seven astronauts to and from the ISS and other low-Earth orbit destinations. The vehicle will launch from Cape Canaveral Air Force Station, just a few miles from its processing facility, and will cruise autonomously on a six to eight hour trip to the $100 billion orbiting ISS. The astronauts will not need to fly the vehicle themselves at all, but will be able to take manual control of the CST-100 at any time, just in case.

“We [Boeing] have a basic level of training we provide that will give the operator, a pilot, the knowledge that they need to operate the spaceship, which is mostly autonomous,” said Ferguson. “They will have the ability to get to the ISS and back, as well as the ability to deal with failures and take manual control if necessary.”

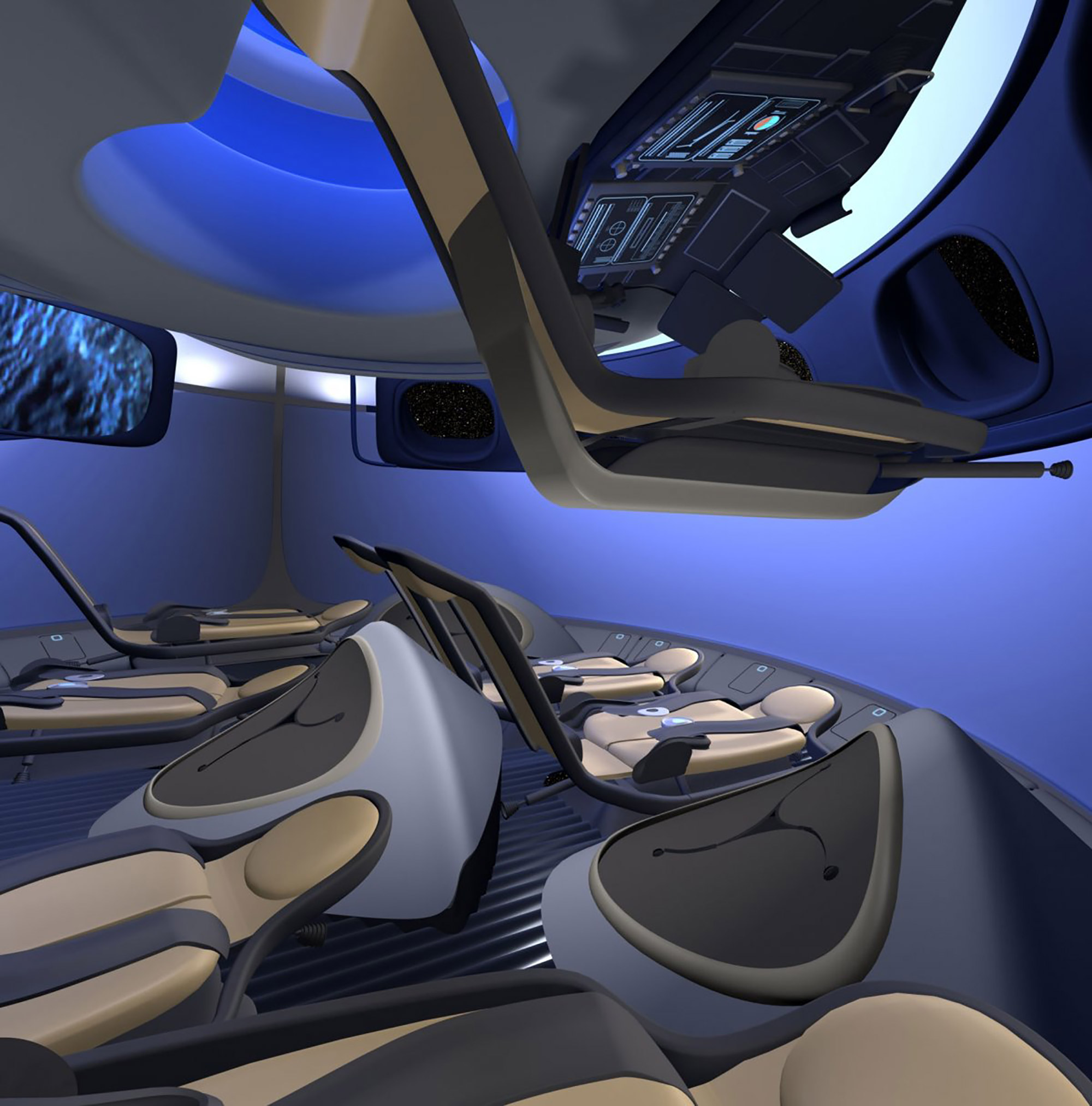

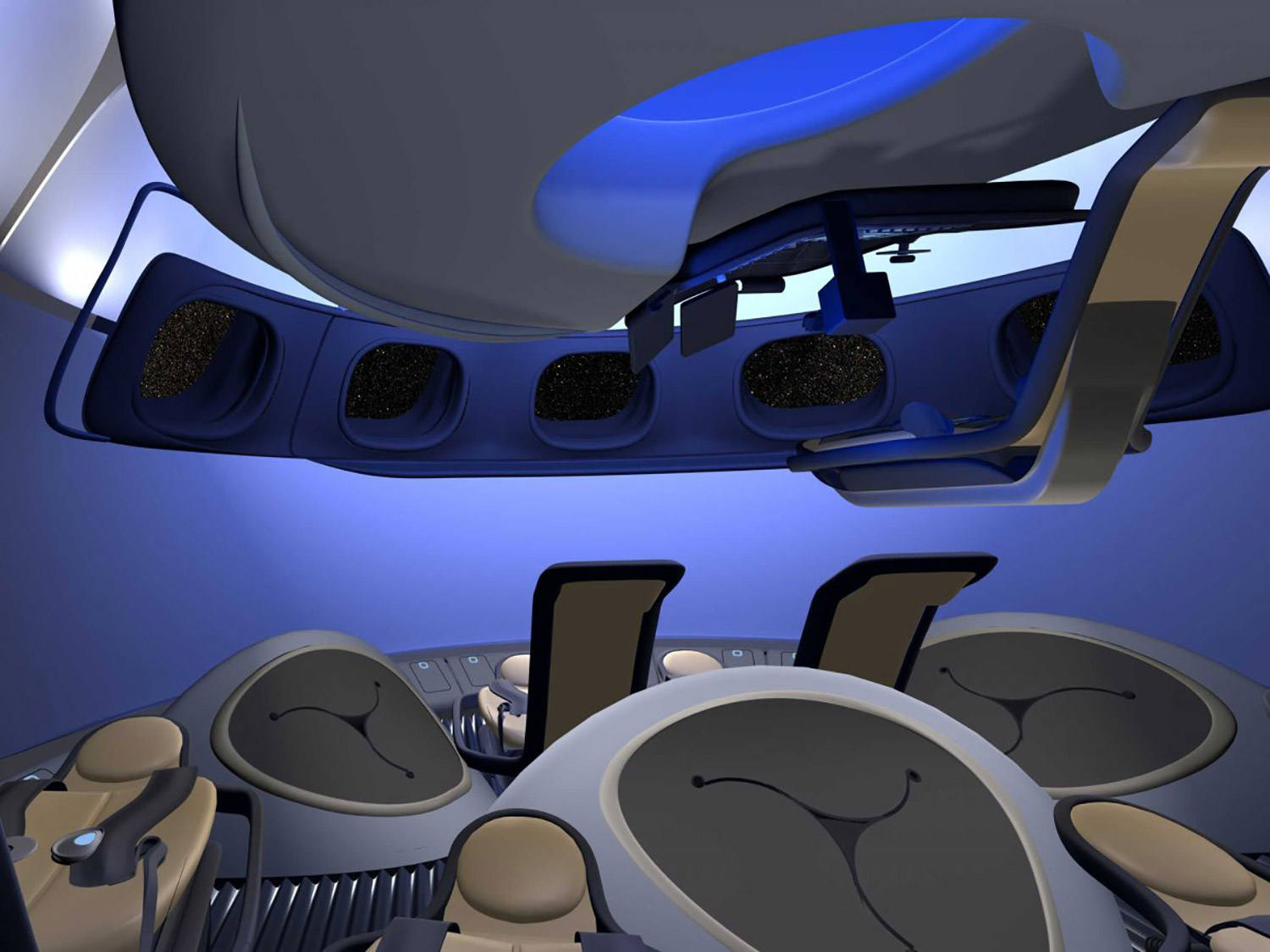

The spacecraft interior is much more user-friendly than vehicles that came before. No more hundreds (if not thousands) of switches on nearly every wall; the CST-100 has a control panel that spans not more than three feet wide. Its look and feel is very user-focused, featuring therapeutic Boeing LED Sky Lighting technology similar to that found in the company’s 787 Dreamliner. A blue hue creates a sky effect and makes the capsule appear and feel roomier, something any astronaut will tell you is always desired (spaceflight is not for the claustrophobic). The interior also boasts tablet technology for crew interfaces, which completely eliminates any need for bulky manuals.

“One of the great things with the technology we have at Boeing is the ability to rapid prototype the interior, and as designs get updated we’re able to bring in new design concepts,” said Boeing CST-100 engineer Tony Castilleja. “We get the engineers in here and get the astronauts in here every six months to provide that reach and visibility. Do they feel comfortable? Is there anything we need to tweak as we move forward? It really builds trust with them. It’s almost like buying a car, but you’re a part of the design process in that vehicle.”

“We brought our commercial airliner feel into the CST-100, and so you see this merging … it’s almost like history repeating itself, from commercial airlines to commercial spaceflight,” adds Castilleja. “We’re bringing that Boeing element into spaceflight and wanted to create an interior that makes the spacecraft feel a little bit bigger.”

If NASA selects Boeing to continue with CST-100 development in the second phase of a two-phased Commercial Crew Program effort this summer, known as Commercial Crew Transportation Capability (CCtCap), then Boeing would move their operations to the Kennedy Space Center to manufacture, assemble, and test the CST-100 flight article.

Boeing, in partnership with Space Florida, is already leasing the former space shuttle Orbiter Processing Facility Bay-3 to do this, modernizing the facility (now known as the Commercial Crew and Cargo Processing Facility, or C3PF) to provide an environment for efficient production, testing, and operations for the CST-100 similar to Boeing’s satellite, space launch vehicle, and commercial airplane production programs.

“We’re transitioning this facility into a world class manufacturing facility,” said Boeing’s CST-100 Program Manager John Mulholland. “With a 50,000 square foot processing facility it’s going to allow us to process up to six CST-100’s at a time.”