It’s May 22, 2014, another bright sunny day at Kennedy Space Center in Florida where a shiny four legged vehicle, dubbed Morpheus, stands in a special area at the north end of the Shuttle Landing facility awaiting the scheduled time to fly. This is the same facility where 78 of the 135 Space Shuttle missions landed.

At the end of the runway, a special area for takeoff and another for landing have been constructed. The landing area is not very forgiving as it has boulders and simulated craters that the lander will have to avoid in order to touchdown in a safe landing spot.

And one more thing, nobody is at the controls, the Morpheus Lander is going to attempt to do this autonomously, or all on its own.

RocketSTEM had the opportunity to visit with Morpheus Project Manager Jon Olansen and Morpheus Ops Lead, Ian Young at the project’s home at Johnson Space Center in Houston, Texas prior to the May 22nd flight.

So what exactly is Morpheus? Morpheus is a reusable, autonomous Vertical Test Bed (VTB), a prototype lander capable of vertical takeoffs and landings. It provides a cost-efficient way to test and refine technologies developed in various NASA laboratories in an integrated flight system.

Morpheus is designed, developed, and tested by a small team at NASA’s Johnson Space Center. From idea board to the first testing was accomplished in just eight months. Other segments of NASA provide their expertise to the project also; Engine testing was done at the Stennis Space Center, the Marshall Space Flight Center provided assistance with the Lander itself as well engine development, Goddard Space Flight Center (GSFC) provided core flight software development, and the Langley Research Center and the Jet Propulsion Laboratory assisted with ALHAT.

The Autonomous Landing and Hazard Avoidance Technology, or ALHAT, is what gives Morpheus the ability to fly autonomously.

The ALHAT system has three critical components, all using lasers as their ways of taking measurements. The trio consists of a flash Lidar system, a laser altimeter, and a Doppler velocimeter. All of these instruments are essential to making a safe autonomous landing. The flash lidar uses imagery technology to detect anything bigger than the size of a basketball, under any lighting conditions.

Flash lidar systems engineer Eric Roback described it as follows, “It’s a flash lidar because the laser flashes and acts like a flash camera”. The Doppler lidar measures the vehicle’s altitude and velocity, allowing it to make a precision landing on the surface. And lastly, the high-altitude laser altimeter provides data enabling the vehicle to land in the chosen area.

As Morpheus Project Manager Jon Olansen told RocketSTEM, “Essentially you give the spacecraft the ability to control its own descent and landing. And that’s what we will be attempting to demonstrate in our flight next week in Florida. Its initial target point in the landing field is right in the middle of the landing pad, irrespective of the rocks and everything.

“It goes and does a scan and identifies within that, what the best place to land is. We know what that should be. From a test perspective we can make sure it lands in the right place, the instruments themselves don’t know we know that. They will be controlling the vehicle and if everything goes as anticipated, they will control the vehicle all the way to the ground and land where it should.

“That’s just an indication of we can make the vehicle think for itself, and autonomously perform these functions that we expect it to do when we send it to the back side of the moon, or near some crater, Mars, an asteroid, or even Europa. Where ever it is that we want to send a craft that you’ll have the capability with the suite of sensors to be able to find a good place and land precisely.”

Lasers were required to perform in all types of lighting and environments. “To get the speed of return that they were looking at, to get the improved performance that they were looking at, and to meet the requirements to land at any time, they determined that the lasers provided the best performance,” said Jon Olansen.

The velocimeter for example, the Doppler velocimeter, it’s a set of three laser beams and that unit itself improves the ability to measure velocity on a spacecraft by almost an order of magnitude, so an almost 10 fold improvement in the ability to measure velocity, how fine you can measure changes in velocity. So it’s a significant instrument improvement over what has existed to date.

There are a lot of people interested in just that instrument by itself. Just that instrument can make a big difference in how you fly, so that precision was one of the reasons.”

Also the distances the instruments are required to operate from was a factor, “The altimeter, you’re going to flying at significant altitudes, you are going to use that for Terrain Relevant Navigation when you are up 10, 20 or more kilometers from the surface.”

This fuel used by the lander is a bit different than most space vehicles in that Morpheus is powered by Liquid Methane and Liquid Oxygen. This combination of fuel is relatively safe compared to other rocket fuels, it’s a clean burning fuel mix, it is nontoxic, and it can provide up to 321 seconds of burns time during space flight using the current tanks on Morpheus.

The fuel also makes testing much easier since the hazard associated with the fuel mixture is minimal compared to most other rocket fuels. It’s referred to as a “Green fuel” since it is not really hazardous outside of its combustibility.

From a storage standpoint, liquid methane does not boil off like liquid hydrogen (LH2). In order to store LH2 you need to keep it very cold, -253C (-423F) to prevent boiling off. The average temperature on Mars for example, is about -60C, so a lander going there would have to have equipment, and fuel to run it, to keep the LH2 chilled.

Using hypergols like the Space Shuttle used for its Reaction Control System (RSC) requires keeping those fuels very warm. Providing this heating or cooling for the propellants would require additional equipment on the lander which adds additional weight to the lander, which would have to be offset by decreasing the payload.

Using liquid methane however, you do not need that extra equipment. This would be useful in terms of a robotic sample return mission, or even a manned landing. One lander carrying fuel as its payload could land well before the actual mission lander arrived. For example, in its current configuration, Morpheus would be capable of placing an 1,100 pound payload onto the Lunar surface.

Also Methane has been detected on Mars and is known to be on Saturn’s moon Titan. If the technology to develop liquid Methane or liquid Oxygen, or better yet, both, on another world is invented, then once the equipment was in place to manufacture the fuels, no further precursor missions would be required.

The team behind all this is a small one. They are part of NASA’s Advanced Exploration Systems (AES) program, which is pioneering new approaches for rapidly developing prototype systems, demonstrating key capabilities, and validating operational concepts for future human missions beyond Earth orbit. AES activities are uniquely related to crew safety and mission operations in deep space, and are strongly coupled to future vehicle development.

According to Project Manager Jon Olansen, “It’s a relatively small project, probably about 45 – 50 civil servants, and 10 – 12 support contractors. We have people from the Jet Propulsion Lab who are considered contractors that are tied in. We have folks from here at Johnson and at Langley Research Center that are considered contractors. We get a lot of support from a lot of different areas.

“Still a relatively small team, but with a wide variety of backgrounds, it’s not one specific interest that drives a spacecraft like this. You could be interested in electronics or electrical engineering, you could be interested in propulsion, you could be interested in operations, you could be interested in the guidance, navigation, and controls aspects, or you could be interested in structures. If you have interest in any one of those areas, they all apply.

“A lot of different interests would have applicability in this, so we have a wide variety of personnel on the team, and they have done a great job of bringing their expertise to the team, as well as learning, because it’s also a very diverse team from an experience level. We have some senior engineers who have been doing things for a long time, and they are sharing their experience and teaching folks. It’s really a great environment for building the team“

According to Morpheus Ops Lead Ian Young, “On a small project like this that requires all those things, the propulsion guy get a better feel and understanding of what the structures guys requires or what he needs and vice-versa. Versus if you are working on a bigger project, you’ve got a propulsion team that has probably 50 people on it by itself, so you don’t get outside of the propulsion area to see how choices you make my impact somebody else. Where as in this, interacting on a daily basis with just about everyone, there are two or three propulsion guys and two or three structure guys, so if the propulsion guy has a problem, he’ll go talk to the structure guy.”

Jon Olansen adds “One of the hardest things to grow in an agency like NASA is Systems Engineering. A lot of people come in with discipline specific interests, like Ian was talking about, propulsion engineering, you like rockets, you want to design and test rockets. But to have someone who understands across all of those different systems and how they have to integrate and helps integrate them is a difficult thing to grow. There aren’t that many opportunities to experience that type of activity and so this is another thing that this project gives to all those people.”

“The lean development was another aspect,” says Jon Olansen. “To try and do it without spending a whole lot of money, to use assets that existed, because this is just a prototype. You don’t want to build a craft that is too expensive to test. You want to make sure you get as much out of it as you can, but not have so much sunk into it that you are afraid of flying it. So that’s a big part of making sure we actually get out there and fly, because we put the vehicle at risk every time we fly.”

Another of the team’s high level goals is education and outreach. Says Jon Olansen, “The fact that you have a RocketSTEM website, that’s right up our alley with what we’ve been doing since we started the project. That’s why all of our tests are streamed live as part of that goal.

“We’ve had over 60 students involved in the project as co-ops or interns over the last three and a half years. We’ve had a couple of high school students as interns as well. We have partnerships with different universities on different aspects of the project. I just received an email from Perdue University, their students have actually built a rocket engine that would fit the Morpheus vehicle and test fired it yesterday. So that’s something we will go advertise as well.”

So how did we get to this test flight? The project itself started in June of 2010 and the first vehicle was ready to fly just eight months later. The first tests on the “Alpha” Morpheus lander were conducted in 2011, and things did not always go well.

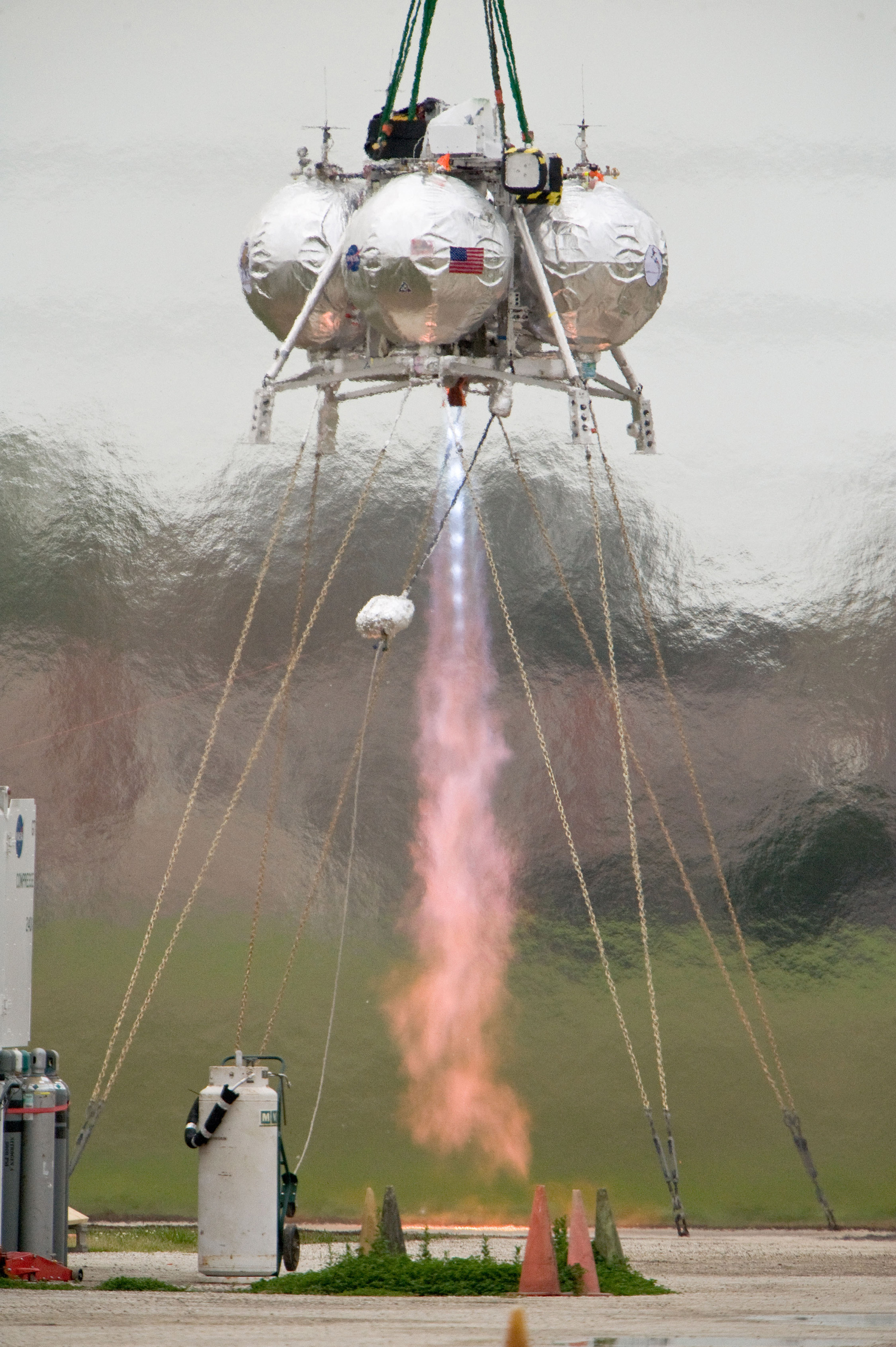

The first test, a tethered test where the lander is suspended from a crane and remains attached to the tether, was supposed to be a 40 second firing where the lander would hover about five feet above the end of the tether, only lasted a few seconds. The vehicle almost immediately pitched over and the thrust termination system ended the test.

Not deterred, the team analyzed the data, made changes and was ready to test again just six days later. A much better outcome resulted and they knew their modifications had them on the right track.

The very next day, another tethered flight gave them even better results. Much work was yet to be done, many more tethered tests and further development of the flight hardware and software would have to occur before any free flights could even be attempted. But the lander was beginning to perform. A total of seven tethered flights were performed before 2011 ended.

In March of 2012, the team rolled out what was essentially a new vehicle. While the structure and Methane / Liquid Oxygen tanks were the same, the vehicle itself was essentially a new vehicle. “The first series of tests gave us a basic understanding of our ability to control the vehicle and allowed us to initially characterize the performance of the subsystems on the vehicle,” Morpheus Project Manager Jon Olansen said. “With that information we were able to go back and design in upgrades to improve performance and reliability.”

Morpheus at this time has a new engine, new avionics, and significant upgrades to the software in preparations for the addition of its Autonomous Landing and Hazard Avoidance Technology (ALHAT) system that will be added later. With all these changes, more tethered tests would need to be performed before any thoughts of free flight could be entertained. A total of 20 tethered tests flights would be conducted before the team would be ready to attempt the first free flight.

The first official free flight occurred on August 9, 2012 with Morpheus lifting off under full power, after just a few seconds the vehicle tumbled over and crashed to the ground in a spectacular fireball. The vehicle was virtually destroyed. Data coming from the Inertial Measurement Unit (IMU), which supplies data to the flight computer so it knows which way is up, down, and so forth stopped relaying. Without the data the vehicle was unable to maintain stable flight and crashed.

It is not unusual for failures to occur in testing new systems and the team went back to the drawing board with the data they had learned up through the failed free flight to build an even better lander.

As Jon Olansen said to us, “When I give presentations, I don’t shy away from problems we’ve had, we don’t try to hide any of that stuff. Usually when I give presentations I start there. Especially to younger audiences, a lot of what we are trying to convey in that setting is that engineering is not a precise science that you always have to get right the first time. It is a learning process.

“Working through failures, and understanding them, advances learning significantly. Taking appropriate risk early enough in your development process allows you to end up with a much better design later on”

It took just eight months from the time of the crash till the debut of the “Bravo” Morpheus lander. Having learned many things from the previous vehicle’s testing, this lander looked the same but 70 upgrades had been made to both the vehicle and the ground systems to improve reliability and operability.

The team had implemented improvements such as advanced engine performance capabilities (while recovering and reusing the primary engine components from the previous vehicle), enhanced communication protocols, redundant instrumentation where appropriate, increased structural margins, and mitigated launch vibroacoustic environments. It was time to test once again.

Starting back with the basics, the team conducted a 50-second static hot fire of the main engine in the vehicle at Johnson Space Center. Included in the test was simultaneous demonstration of thrust vector control (TVC) and integrated methane reaction control system (RCS) jet firings. Thrust vector control is used to balance and fly the vehicle, while the RCS jets are used to keep the vehicle pointed in the correct direction. All worked well and once again tethered flights soon followed, and finally a return to Kennedy Space Center for more testing up to the first free flight attempt of the Bravo vehicle.

Ian Young describes some of the other testing done at Kennedy other than the free flights, “We have a simulation capability, so that the Operations team, the folks who sit at the consoles, will actually go up to the Control Center the day before and we’ll run through 8 to 10 runs of the flight we are planning to run the next day. We put in failures and react to those. It’s good for the team to see the planned trajectory and to talk through any responses to failures. Those SIMS have brought about idea on how we could improve our current design.

We have done a number of tests that aren’t flight tests out in Florida also. Sometimes the only way to get integrated data is too actually take the vehicle out and swing it on a crane so we get motion on the vehicle, so that the ALHAT sensors and the vehicle can see that motion, and make sure they are coming to the right solution without actually lighting the engine.”

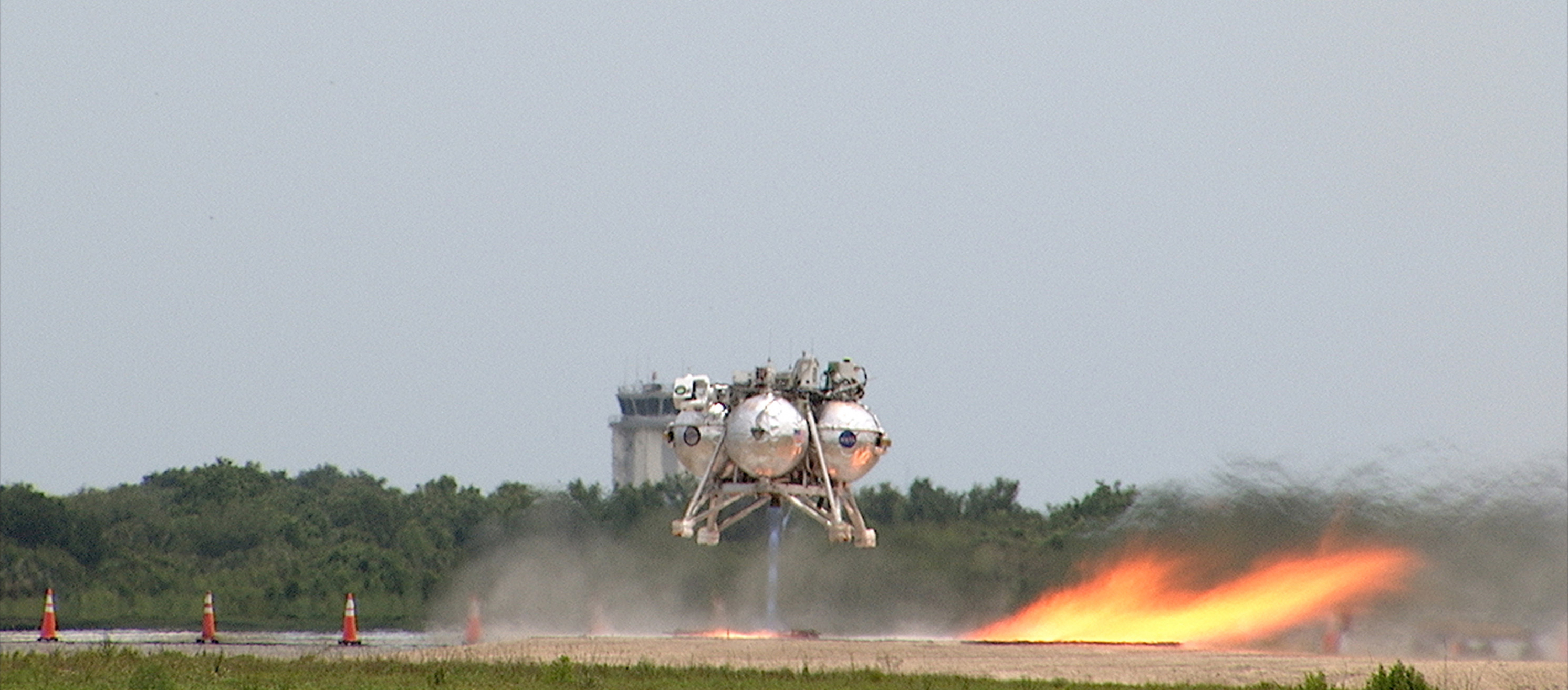

The Bravo vehicle roared to life at the north end of the Shuttle Landing Facility on December 10, 2013 to attempt its first free flight. It rose spectacularly on its single rocket engine’s pillar of fire, like a ball balancing on the end of a straw. It flew almost flawlessly, rising to about 50 feet in altitude, hovering in place before moving to a landing spot approximately 23 feet from the takeoff spot, landing after about 50 seconds of powered flight. The team had done it; they had a vehicle that could fly. Less than a week later, Morpheus flew again, going higher, faster, and further in an 82 second free flight.

Ten more free flights would be conducted over the next four months, which brings us back to where this journey started, at Kennedy Space Center on May 22, 2014. This will be the 13th free flight for Morpheus, but this one is different than all of the prior 12 since all of those have been “open loop” tests where the team could jump in and take over if need be. This will be the first “closed loop” test, Morpheus will be in complete control of its flight for the first time. The training wheels are off, it’s time to fly solo.

The first “closed loop” free flight begins as the engine of the lander ignites and the Bravo vehicle climbs to about 800 feet in altitude, there it hovers and does what is called its Terrain Relative Navigation to make sure the lander knows where it is in relation to the landing site. The lander then moves toward the designated landing area which is a quarter of a mile away from the takeoff spot. ALHAT is surveying the landing area making sure things look good.

While the lander has a designated landing site in the landing field already programmed, that site is littered with boulders and Morpheus should decide that it is not a viable landing spot. Using the information from ALHAT, the lander finds the only appropriate area in the landing field, a concrete pad covered in simulated lunar soil. Its flight path is changed and it lands right where it is supposed to.

Morpheus made another “closed loop’ free flight just six days later. This time though it occurred at night, proving that the lander will perform in any lighting conditions. The 98 second flight proved that the lander is capable of, if needed, entering a completely dark crater and finding an appropriate landing spot, or landing on the dark side of a planet, moon, or an asteroid, where little to no light shines.

So what comes after the testing at Kennedy is done? Jon Olansen speculated on that during our visit, “There are a lot of different things that we can do to continue to evolve the technologies. The ALHAT suite of sensors, we will have demonstrated what we call TR Level 6, Technology Readiness Level 6, really they are ready for a mission to pick them up and make them spaceflight ready. They will have demonstrated that the capability exists, it’s feasible, the algorithms work, and NASA just needs to package them appropriately for spaceflight. That would happen on a specific mission, a follow-on to Mars, the asteroid retrieval mission, or whatever that mission is, if they are looking for any of the sensors, or a combination of all three, that’s where they’ll pull it.

“We’ve pushed it to the point where it’s ready, and other missions will pick it up and make it spaceflight ready.

“With the LOX and Methane, we need to advance the type of engine that is actually in the vehicle. We need to go to an engine that is actually ready for spaceflight. So, a regeneratively cooled engine where you are actually cooling the nozzle, not with film cooling like we use now, which we’re actually flowing cold methane down the inside of the nozzle, but you actually having it flowing through the nozzle to keep it cool. It’s more efficient that way and so you can get better performance out of the engine. Some of that development work has to happen in test stands, before you would put it on a vehicle.

“So there’s some aspect where we reach a point with the vehicle, now we‘re going to have to step back off, make some advances outside the vehicle, and then look at when we have to test again in an integrated flight environment. Right now, we don’t have specific tests laid out, beyond Kennedy testing for these vehicles, but they are available as we evolve.”

The night flight would be the 14th and last free flight for Morpheus, at least for now. The Morpheus project, while not done, is at least a stopping point as far as flying goes. What will come next for the lander, and its talented team is yet to be determined.

The ALHAT technology is apparently proven and hopefully will be used someday soon to land a rover, fuel, or even astronauts on a surface other than Earth’s. Further development of the LOX / Methane propulsion system will hopefully see the Vertical Test Bed lander fly longer, higher, and further than ever before.

ALHAT: Key Mission Facts

• The Autonomous Landing and Hazard Avoidance Technology project will provide a state-of-the-art automated descent and landing system for planetary lander craft.

• Precision landing will be based on a sophisticated, surface-tracking sensor suite with real-time hazard avoidance capabilities – assessing altitude and velocity of the descending vehicle and the topography of the landing site.

• ALHAT algorithms combined with sensor data will navigate the descending craft to the “pre-mission landing aim point,” where it will quickly and autonomously identify safe landing areas and help guide the craft to touchdown.

• The technology provides an unprecedented procedure for safe planetary landing procedures – for future crewed as well as robotic missions.

• The technology works in any lighting conditions – from the harsh glare of an unshielded sun to the cloudy, gaseous murk of a distant solar system body.

For more information about ALHAT, visit: http://alhat.jpl.nasa.gov/.

For more information about Project Morpheus, visit: http://morpheuslander.jsc.nasa.gov/.

For more information about NASA’s Advanced Exploration Systems program, visit: http://www.nasa.gov/directorates/heo/aes/#.U5HcNvldXuQ.