In 2010, with the retirement of NASA’s iconic 30-year space shuttle program, the space agency began the Commercial Crew Program to stimulate development of privately built and operated American-made spacecraft for transporting astronauts to and from low-Earth orbit (LEO) and the International Space Station (ISS). Since the final shuttle landed in 2011, America has been forced to buy seats to and from the orbiting outpost on the Russian Soyuz capsule, at a cost of over $70 million, per seat. Now, after over four years of testing, development, and waiting, NASA has selected Boeing’s CST-100 space capsule and SpaceX’s Dragon V2 space capsule to replace the agency’s now-retired space shuttle fleet for flying astronauts to and from LEO and the ISS no later than 2017.

“Turning over LEO transportation to private industry will allow NASA to focus on an even more ambitious mission – sending humans to Mars,” said NASA Administrator Charlie Bolden. “We don’t know who is going to get to command the first mission to carry humans into LEO on a spacecraft built by an American private company, but we know it will be a seminal moment in NASA history and a major achievement for our nation. We now know, however, who will build it.”

The total award value of their Commercial Crew Transportation Capability (CCtCap) contracts are worth up to $6.8 billion, with $4.2 billion for Boeing and $2.6 billion for SpaceX, and in order to achieve final NASA certification by 2017 both Boeing and SpaceX must meet the same rigorous safety standards that were required for the space shuttle. NASA has stated that Boeing is the agency’s primary transport vehicle of choice, with SpaceX’s Dragon V2 awarded as a backup. There’s the old saying, “money talks,” and NASA potentially awarding Boeing $1.6 billion more than SpaceX shows the agency has more confidence in Boeing’s experience and the CST-100’s design, despite the fact that some might not like to hear it. Not only that, but off the record several anonymous sources within NASA have expressed the same.

Additionally, the awards are dependent on Congressional funding; if Congress does not make the requested funds available, then the actual awards will be less, so NASA wants to make sure that if that does happen the CST-100 will still have adequate funds available to become a reality and start carrying crews to and from the ISS from American soil sooner rather than later.

Per the terms of the contract, each company must fly at least one crewed flight test, with at least one NASA astronaut aboard to verify the fully integrated rocket and spacecraft system can launch, maneuver in orbit, and dock to the ISS, as well as validate that all its systems operate as expected throughout the mission. Once Boeing and SpaceX have completed their test programs successfully and earned NASA certification, they will conduct at least two, and as many as six, crewed missions to the ISS for NASA. Both vehicles will also serve as lifeboats for crew living on station in case of an emergency, as well as serving other potential customers besides NASA.

The Boeing CST-100 crew space transportation system

“It feels great to be building this, not only for Boeing but for the entire country,” said Boeing CST-100 engineer Tony Castilleja in a telephone conversation we had hours after NASA announced their award decision. “I grew up inspired by space shuttle, and this will inspire a whole new generation. Seeing where we are headed, it’s a testament to the hard work of our team, I haven’t seen a passion like this ever, there’s a passion to the work that each and everyone does on this program, and I think that’s shown in the past with our ability to meet our milestones on time, as promised, and it’s going to show at the launch pad come 2017.”

With their award now secured, Boeing is picking up the pace with building three flight articles, each capable of 10 orbital flights each, and each flight article will serve to fulfill NASA’s CCtCap requirements for certification and regular crew transportation flights.

“The CST-100 is a cheap, cost effective vehicle that does not need to be luxurious because it only needs to hold people for 48 hours. It’s a simple ride up to and back from space,” said former astronaut and commander of the last space shuttle mission Chris Ferguson, who now serves as Director of Crew and Mission Operations for Boeing. “Our focus right now is making sure we build the vehicle the right way.”

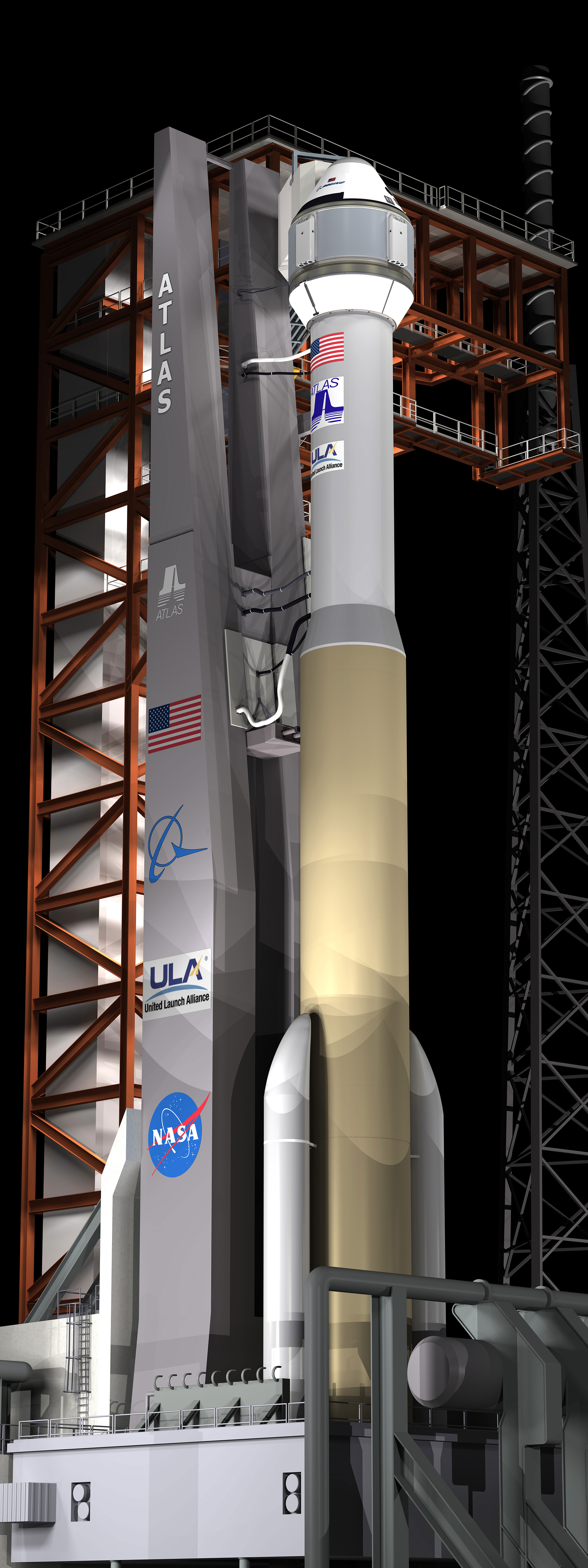

CST-100 will launch initially atop ULA’s Atlas V rocket and be capable of ferrying a crew of up to seven astronauts to and from the ISS. NASA only requires seating for four, but Ferguson has said he expects crews of at least five to fly. The vehicle will launch from Cape Canaveral Air Force Station, just a few miles from its processing facility, and will cruise autonomously on a six to eight hour trip to the $100 billion orbiting ISS. The astronauts will not need to fly the vehicle themselves at all, and will literally be along for the ride in all aspects of the flight. They will, however, be able to take manual control of the CST-100 at any time, just in case.

“We have a basic level of training we provide that will give the operator, a pilot, the knowledge that they need to operate the spaceship, which is mostly autonomous,” added Ferguson. “They will have the ability to get to the ISS and back, as well as the ability to deal with failures and the ability to take manual control if necessary. NASA wants a single piloted vehicle, so we will train the pilot to whatever level of proficiency they need, and if NASA wants us to train someone else to a pilot level of proficiency then we will be happy to do that. That being said we have factored into our design the ability for a copilot, and train them perhaps to the same level of proficiency as the pilot. They would sit beside the pilot and do all of those types of crew resource management (CRM) types of things that NASA instilled in us shuttle astronauts over the years.”

“When astronauts go up in the CST-100 their primary mission is not to fly the spacecraft, their primary mission is to go to the space station for 6 months, so we don’t want to burden them with an inordinate amount of training to fly our vehicle,” added Ferguson.

The spacecraft interior is much more user-friendly than vehicles that came before, no more hundreds (if not thousands) of switches on nearly every wall; CST-100’s control panel spans not more than three feet wide. Its look and feel is very user-focused, featuring therapeutic Boeing LED Sky Lighting technology similar to that found in the company’s 787 Dreamliner. A blue hue creates a sky effect and makes the capsule appear and feel roomier, something any astronaut will agree is always desired (spaceflight is not for the claustrophobic). The interior also boasts tablet technology for crew interfaces, which completely eliminates any need for bulky manuals, while wireless internet will support communications and ISS docking operations.

“One of the great things with the technology we have at Boeing is the ability to rapid prototype the interior, and as designs get updated we’re able to bring in new design concepts,” said Castilleja while we sat together onboard his CST-100 mock up last June at Boeing’s CST-100 processing facility at KSC. “We get the engineers in here and get the astronauts in here every six months to provide that reach and visibility. Do they feel comfortable? Is there anything we need to tweak as we move forward? It really builds trust with them. It’s almost like buying a car, but you’re a part of the design process in that vehicle.”

“We brought our commercial airliner feel into the CST-100, and so you see this merging … it’s almost like history repeating itself, from commercial airlines to commercial spaceflight,” added Castilleja. “We’re bringing that Boeing element into spaceflight and wanted to create an interior that makes the spacecraft feel a little bit bigger.”

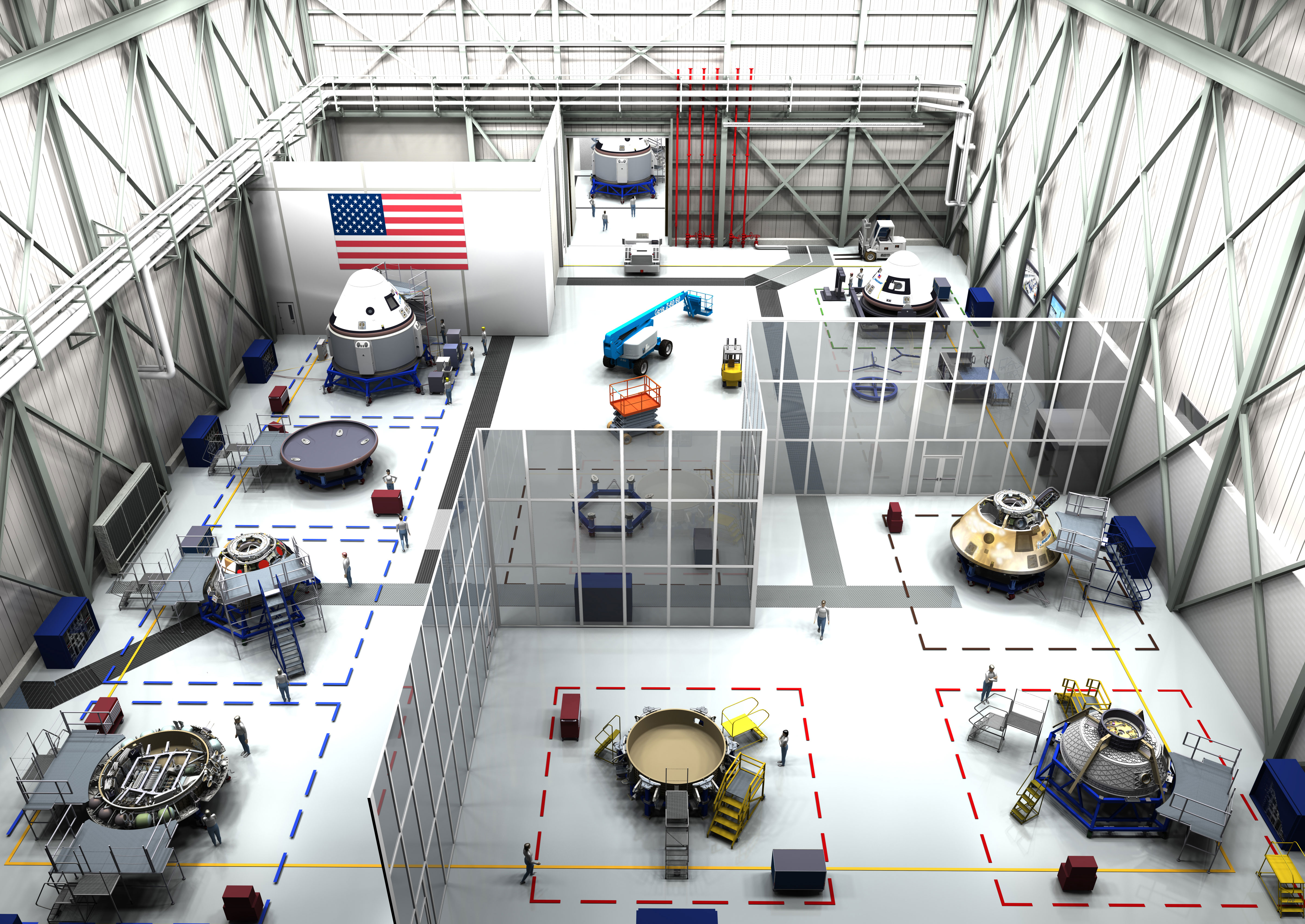

Now that Boeing has secured their award with NASA, operations will immediately move to the Kennedy Space Center (KSC) to manufacture, assemble, and test the actual CST-100 flight articles. Boeing, in partnership with Space Florida, is already leasing the former space shuttle Orbiter Processing Facility Bay-3 at KSC to do this, modernizing the facility (now known as the Commercial Crew and Cargo Processing Facility, or C3PF for short) to provide an environment for efficient production, testing, and operations for the CST-100 similar to Boeing’s satellite, space launch vehicle, and commercial airplane production programs.

“We’re transitioning this facility into a world class manufacturing facility,” said Mulholland. “With a 50,000 square foot processing facility it’s going to allow us to process up to six CST-100’s at a time.”

The hangar facility has more than enough room to support processing of multiple CST-100s simultaneously, and the adjoining sections of the building are well-suited to process other systems such as engines and thrusters before they are integrated into the main spacecraft. Boeing will also bring 300, and eventually 500, new jobs to Florida’s “Space Coast,” whose economy was hit particularly hard at the end the shuttle program.

“This facility will become point and center, we’ll be developing the test articles here and then starting the manufacturing for full services in 2017,” added Castilleja. “This is where all the pieces and parts will come in, and we’ll then build everything right here. One side of the building is for processing the service modules, and the other side of the facility is for processing the crew modules. We’ll then ship out to the Atlas launch pad integration facility and off we go.”

The SpaceX Dragon V2 crewed space capsule

“SpaceX is deeply honored by the trust NASA has placed in us,” said SpaceX CEO Elon Musk in a statement this afternoon. “We welcome today’s decision and the mission it advances with gratitude and seriousness of purpose. It is a vital step in a journey that will ultimately take us to the stars and make humanity a multi-planet species.”

Musk unveiled his Hawthorne, Calif.-based company’s new Dragon spacecraft, the Dragon V2, at SpaceX Headquarters in southern California last May.

“When we first created Dragon V1 we didn’t really know how to create a spacecraft, we never designed a spacecraft before, so, while there are a lot of interesting technologies in Dragon V1 it does have a relatively conventional landing approach by throwing off parachutes and landing in water off the coast of CA after it comes back from the ISS,” said Musk, moments before dropping the curtain on Dragon V2. “It’s a great spacecraft and a great proof of concept, it showed us what it took to bring something back from orbit, which is a very difficult thing to do, but going from V1 we wanted to take a big step in technology.”

SpaceX currently flies their Dragon V1 to carry out a $1.6 billion Commercial Resupply Services (CRS) contract with NASA, signed in late 2008, to conduct 12 dedicated Dragon resupply missions to the ISS by 2016, missions which promise to haul a total of 44,000 pounds of equipment and supplies to the orbiting outpost. Dragon V1 was the first commercial spacecraft to visit the ISS, and the first commercial spacecraft to return to Earth from orbit. It has flown to, and from, the ISS four times, starting with the inaugural Commercial Orbital Transportation Services (COTS) Demo mission in May 2012 and followed by the dedicated CRS-1 and CRS-2 missions in October 2012 and March 2013, the CRS-3 mission last April, and most recently the CRS-4 mission just last month.

However, Elon Musk has always said he wants to bring American human spaceflight capability back to the nation and give humanity the means to become a multi-planet species, at much cheaper than any government can do, and even though the Dragon V1 does have a life-support system it’s not one that can last for a long time or carry a lot of people. That’s where the Dragon V2 comes in, and its landing method will be quite different, too.

“Dragon V2 still retains the parachutes of Dragon V1, but V2 will be able to land anywhere on land propulsively, and do so anywhere on Earth with the accuracy of a helicopter, which is something I think a modern spaceship should be able to do,” said Musk. “When Dragon V2 reaches a particular altitude a few miles before landing it will test the engines and verify that all the engines are working before proceeding to a propulsive landing, and if there is any anomaly detected with the engines or propulsion system it will then deploy the parachutes to ensure a safe landing, even in the event that the propulsion system is not working. All around I think it’s really a big leap forward in technology, it really takes things to the next level.”

engines for both launch aborts and for controlled powered landings. Credit: SpaceX

“Even after starting the propulsion system it can afford to lose up to two engines and still land safely,” added Musk. “After the engines are started it will then deploy the landing legs for a soft landing. This is really important, apart from the convenience of the landing location, because it enable rapid reusability of the spacecraft, you can just reload propellants and fly again. This is extremely important for evolutionizing access to space because as long as we continue to throw away rockets and spacecraft we will never truly have access to space, it will always be incredibly expensive.”

Musk offered the following scenario for comparison:

“If aircraft were thrown away after each flight then nobody would be able to fly, or very few, maybe a small number of customers. The same is true of rockets and spacecraft, so that’s really why it’s so important to be able to land propulsively, land on land and be able to reload propellants and take off again.”

The biggest upgrade, at least from a propulsion standpoint, is the addition of the SuperDraco engines, a “superpowered” version of the Dragon V1 Draco engines used to maneuver in space and control the spacecraft’s trajectory during reentry. Dragon V2 will still use the original Draco thrusters for maneuvering in space, but the V2’s SuperDraco thrusters will serve both as part of the vehicle’s launch escape system and enable propulsive landing on land. A total of eight SuperDraco’s are built into the side walls of the Dragon V2 and will produce up to 120,000 pounds of axial thrust (16,000 pounds of thrust each, compared to 100 pounds of thrust each with the original Draco thrusters). The engines also come in pairs, so if one engine fails the other can increase its thrust to compensate for the engine that is not firing.

The SuperDraco engines on the Dragon V2 are also the first fully 3-D printed engines intended for space. The chamber is regeneratively cooled and printed in Inconel, a high-performance superalloy that offers both high strength and toughness for increased reliability; they will become the first printed rocket engines ever used in spaceflight. It was only a couple days ago that SpaceX completed qualification testing for the SuperDraco thruster at the company’s Rocket Development Facility in McGregor, Texas, which included testing across a variety of conditions including multiple starts, extended firing durations, and extreme off-nominal propellant flow and temperatures.

“Through 3-D printing, robust and high-performing engine parts can be created at a fraction of the cost and time of traditional manufacturing methods,” said Musk. “SpaceX is pushing the boundaries of what additive manufacturing can do in the 21st century, ultimately making our vehicles more efficient, reliable and robust than ever before.”

Where does this leave Sierra Nevada’s Dream Chaser?

As with any competition, there must be a loser. Sierra Nevada’s Dream Chaser “mini space shuttle” did not secure a CCtCap award from NASA. However, that does not mean we will never see a Dream Chaser fly, it just means we won’t see NASA giving them extra money to continue development to serve the space agency’s agenda for contracting with private companies for crew transport to and from the ISS.

However, soon after the award decision was announced Sierra Nevada Corporation (SNC) filed a “legal challenge” with the Government Accountability Office (GAO) protesting NASA’s selection of Boeing and SpaceX, stating that, “NASA’s own Source Selection Statement and debrief indicate that there are serious questions and inconsistencies in the source selection process.”

Pursuant to the GAO protest filed by SNC on Sept. 26 NASA was forced to issue a “stop work order” instructing both Boeing and SpaceX to stop performance of their newly awarded Commercial Crew contracts. However, a couple weeks later NASA decided to exercise their “statutory authority” and press on with Boeing and SpaceX contracts despite SNC’s protest with the GAO.

“The agency recognizes that failure to provide the CCtCap transportation service as soon as possible poses risks to the ISS crew, jeopardizes continued operation of the ISS, would delay meeting critical crew size requirements, and may result in the U.S. failing to perform the commitments it made in its international agreements. These considerations compelled NASA to use its statutory authority to avoid significant adverse consequences where contract performance remained suspended. NASA has determined that it best serves the United States to continue performance of the CCtCap contracts that will enable safe and reliable travel to and from the ISS from the United States on American spacecraft and end the nation’s sole reliance on Russia for such transportation.”

Regardless of the outcome between SNC and NASA, SNC Space Systems VP Mark Sirangelo has made it loud and clear that the company is ready to move forward with development of the Dream Chaser without NASA, as long as there is a business case for it, and that business case may come in the form of international cooperation with the European Space Agency (ESA) and the Japan Aerospace Exploration Agency (JAXA).

Sierra Nevada has already begun to build their first Dream Chaser for an inaugural orbital flight test atop a ULA Atlas-V rocket in late 2016, and they have already purchased the Atlas-V for that flight. Whether that flight actually occurs though we will have to wait and see.

“Our destiny is set. Our course is laid out before us. And we are following it,” added Bolden after announcing NASA’s decision. “We hope the American people will be inspired to join us on this next great, ambitious leg of humanity’s journey farther into our solar system than ever before.”

“I can’t put into words what it will feel like to see years of hard work payoff when that first CST-100 launches,” added Boeing’s Tony Castilleja at the end of our most recent conversation. “When we launch the CST-100 on that Atlas-V rocket I can’t wait to look to the left of me, to the right of me, and see the friends and the passion that each and everyone put together to launch this off, and I can’t wait to see our astronauts return home on our vehicle safely.”